OVERVIEW

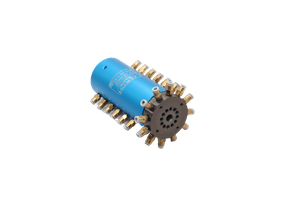

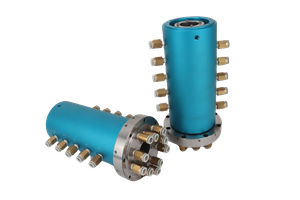

The hydraulic rotary union( hydraulic swivel joint) can be choose the connecting method according to the working conditions.

There are independent pipelines inside, which can be selected for different working conditions to maximize the function. There are two precision bearings inside. The operation is stable, durable, reliable, flexible and flexible, and the friction coefficient is small, so it can run at high speed. In general, hydraulic swivel joints are typically equipment for delivering hydraulic media to hydraulic actuators or the other the rotating equipment.

Options (Based on requirements)

1) Type of fluid, or medias to be transferred

2) Passages(channels)numbers for transterred

3) Operating speed(rpm)

4) Operating pressure

5) Operating temperature

6) Size of every Passages(channels) for flow

Material: | Stainless Steel | Housing Material: | Ss304 |

Size: | 3/8''-4'' | Technics: | Casting |

Type: | Coupling | Connection: | Threaded Connection |

Medium: | Water,gas,oil | Max Speed: | 300RPM |

Max Pressure: | 3.5Bar | Max Temperature: | 120℃ |

DIMENSION DRAWING

It is only a drawing example here. Normally it is OEM models, Every design is based on different requirement.

The slip rings Length is based on the circuits quantity ¤t.

MODEL NO.

APPLICATION FIELD

The application field for hydraulic slip rings are covering almost every processing and manufacturing industry.

For example: metallurgy, machine tools, power generation, petroleum, rubber, plastics, textiles, printing and dyeing, pharmaceutical, cigarette, paper, food, feed processing equipment

PACKAGE & DELIVERY

Package is by carton or by wooden.

Delivery: By Air, by Express, or by sea. Up to customers’ request.

These hydraulic rotary unions are engineered to withstand high pressures and provide a reliable seal, ensuring efficient transfer of fluids without leakage. They come in various designs and configurations to accommodate different pressure ranges, speeds, and fluid types based on the specific requirements of the application.

Hydraulic rotary unions offer several advantages:

1.Continuous Fluid Transfer

2.Leak-Free Operation

3.High Pressure and Speed Capability

4.Versatility in Application as request

5.Customization Options

6.Reduced Wear and Maintenance

There are various types of rotary unions, Some of the common types include:

1.Single Passage Rotary Unions: These are basic rotary unions designed to transfer a single fluid or medium between stationary and rotating parts. They're used in simple applications where only one type of fluid needs to be transferred.

2.Multi-Passage Rotary Unions: These units have multiple channels or passages, allowing the transfer of more than one type of fluid or multiple functions between the stationary and rotating parts. They are used in applications that require the simultaneous transfer of different fluids or functions.

3.High-Speed Rotary Unions: These are designed to handle high rotational speeds without compromising performance or causing damage. They are crucial in applications where there's a need for rapid rotation while transferring fluids.

4.High-Pressure Rotary Unions: Specifically built to withstand and transfer fluids at high pressures. Industries such as hydraulic systems, manufacturing, or heavy machinery often require high-pressure rotary unions for fluid transfer.

5.Pneumatic Rotary Unions: Designed to transfer air or gas between stationary and rotating parts. These are used in applications such as pneumatic systems, air compressors, or other air transfer applications.

6.Hydraulic Rotary Unions: These are specialized for transferring hydraulic fluids between stationary and rotating parts. They are commonly used in hydraulic machinery, heavy equipment, and other applications requiring hydraulic power.

7.Multi-Media Rotary Unions: These unions can handle various types of media, including liquids, gases, or a combination of both. They are versatile and suitable for applications that involve multiple media types.

8.Coolant Rotary Unions: Specifically designed for transferring coolants or liquids in applications like cooling systems in manufacturing equipment, machining tools, or other cooling applications.

9.Water Hydraulic Rotary Unions: Tailored for transferring water or water-based fluids. These can be used in various applications, including water treatment systems, food processing, or any industrial process requiring water transfer.

10.Custom or Specialized Rotary Unions: We can design rotary unions to meet specific or unique application requirements. Such as size, passages, materials, or other specifications to fit the applications.

Rotary unions Materials:

Rotary unions are typically made from a variety of materials, depending on the specific requirements of the application, the type of fluids being transferred, and environmental factors.Normally, the materials of rotary unions are as following:

1.Stainless Steel: Stainless steel is a popular choice due to its corrosion resistance and durability. It is suitable for a wide range of fluids, including water, oil, and various chemicals.

2.Brass: Brass is another corrosion-resistant material commonly used in rotary unions. It is often chosen for applications involving water, air, and certain non-corrosive fluids.

3.Aluminum: Aluminum is lightweight and corrosion-resistant, making it suitable for certain applications where weight is a consideration. It is commonly used in air and water transfer applications.

4.Carbon Steel: Carbon steel is robust and durable, making it suitable for applications involving high pressures and heavy-duty industrial processes.

5.Bronze: Bronze is a material known for its corrosion resistance and wear resistance. It may be used in applications where these properties are critical.

6.Specialized Alloys: Depending on the specific requirements of the application, specialized alloys may be used to enhance properties such as corrosion resistance, heat resistance, or wear resistance.

It is only some series model samples here. If it can not find the model you need.

Contact us here. Let us know with your requirements. Our JARCH designer & engineer team have the full experiences to custom design and produce high reliable slip rings/rotary unions/rotary joints/connectors for you.