OVERVIEW

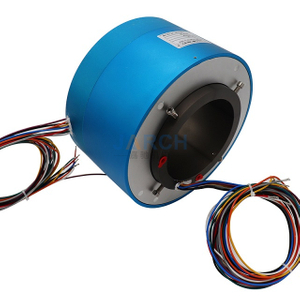

Inner Diameter: 60mm

Outer Diameter: 130mm

Explosion-proof Category: intrinsically safe and flameproof

Explosion-proof Grade: dⅡCT4, EExdIICT5, etc

Explosion Slip Rings Series No.: JSR-EP060 |

Certified Mark: | EX D IIC T6 Gb,DIP A21 Ta,T6 | Inner Size: | 60 mm |

Outer Size: | 130 mm | Lead Wire: | UL Teflon® Awg26,Awg22 |

Lead Length: | 200mm | Housing Material: | Stainless Steel |

Contact Material: | Precious Metal:Gold-Gold | Circuits: | 2--24 |

Currents: | 2A/5A/50A | Voltage: | 400Vac/Vdc |

Max Speed: | 100RPM | Protection: | IP66 |

Electrical Technical Parameters |

Power | Signal |

Spec. | Data | Spec. | Data |

Voltage range | 0-380VAC/VDC | Voltage range | 0-380VAC/VDC |

Insulation Resistance | ≥1000MΩ/500VDC | Insulation Resistance | ≥1000MΩ/500VDC |

Lead wire spec. | AWG16# Tinned Teflon | Lead wire spec. | AWG22# Tinned Teflon |

Rated current | Optional current for each channel |

Electrical noise | 10mΩ@6VDC,50mA,5Rpm |

Dynamic resistance change | <0.01Ω |

Mechanical Data |

Mechanical Performance | Environmental Performance |

Spec. | Data | Spec. | Data |

Working Life | > 50 million revolutions (depends on working conditions) | Operating Temperature | -30C°-80C° |

Rated Speed | 300MRP(can be customized ) | Working Humidity | 0-85%RH |

Contact Material | Precious Metal (can be customized ) | Mechanical Vibration | MIL-SID-810E |

Shell Material | Stainless Steel (surface hard oxidation treatment) | IP Grade | IP51( IP65、IP68 Optional) |

Rotational Torque | 0.1N.M;+0.03N.M/ channel | Explosion-proof category | Coal safety explosion-proof, gas explosion-proof, dust explosion-proof |

Explosion-proof level | T1/T2/T3/T4/T5/T6 Optional

|

The Exprosion-proof slip rings features:

1)The temperature range can be in hig T6 class, it can be full meet T1~T6 working condition requirement;

2)It can meet the explosive gas or explosive dust working environment. It is no problem to work in the 21 District, 22 District, 1 District, 2 District, etc

3)Protection class is IP66, IP68 for optional

4)It is meet the stardard of our contry , and got the Certfication of Conformity.

5)Explosion marking: Ex d IIC T6 Gb, DIP A21 TA,T6

6)The power and signal can pass in one circuit.

7)The working operating environment temperature can be in -30 ~ 60 C

Options (Based on requirements)

1)Size(Inner Diameter, Outer Diameter, Length)

2)Current(mas)

3)Voltage [AC/DC] (max.)

4)Circuits quantity

5)Cable Length

6)Temperature Range

7)Operating Speed (max.)

DIMENSION DRAWING

It is only a drawing example here. Normally it is OEM models as our customer's request,

Every design is based on different requirement.

The size of Explosion-proof slip rings are based on the different working environment

INSTALLATION INSTRUCTION

MODEL NO.

APPLICATION FIELD

Laminating Equipment,lift Equipment, Medical equipment, Industrial cable reels, Oil platform, Explosion-proof packing machine, Spraying equipments, Chemical equipments, Farming industry

PACKAGE & DELIVERY

Package is by carton or by wooden.

Delivery: By Air, by Express, or by sea. Up to customers’ request.

An explosion-proof slip ring is a specialized electrical component designed for use in potentially hazardous environments where there is a risk of explosive gases or dust.

Explosion-proof slip rings are constructed with materials and design features that minimize the risk of sparking or ignition in environments where explosive atmospheres may be present. These environments can include areas where flammable gases, vapors, liquids, or combustible dusts are present, such as in chemical plants, oil refineries, or certain industrial settings.

Main information of explosion-proof slip rings may include:

Enclosure Design: The slip ring is enclosed in a robust housing that prevents the release of sparks or hot particles that could ignite the surrounding atmosphere.

Material Selection: Non-sparking materials and coatings are used to minimize the risk of friction-induced sparks. This might involve using materials like stainless steel or other non-ferrous alloys.

Sealing: Explosion-proof slip rings often have effective sealing to prevent the ingress of gases or dust, maintaining the integrity of the housing.

Certifications: These slip rings typically comply with specific industry standards and certifications for hazardous locations, such as ATEX (European Union), IECEx (International), or other regional standards.

Designing an explosion-proof slip ring requires careful consideration of various factors to ensure the safety and functionality of the device in hazardous environments. Normally, we need the following requirement details

Hazardous Area Classification

Explosive Atmosphere Characteristics

Temperature Class

Friction and Wear Considerations:

Electrical Specifications. including voltage, current, and signal types. Ensure that the slip ring can handle the expected electrical loads and number of Circuits.

It is only some series model samples here. If it can not find the model you need.

Contact us here. Let us know with your requirements. Our JARCH designer & engineer team have the full experiences to custom design and produce high reliable slip rings/rotary unions/rotary joints/connectors for you.