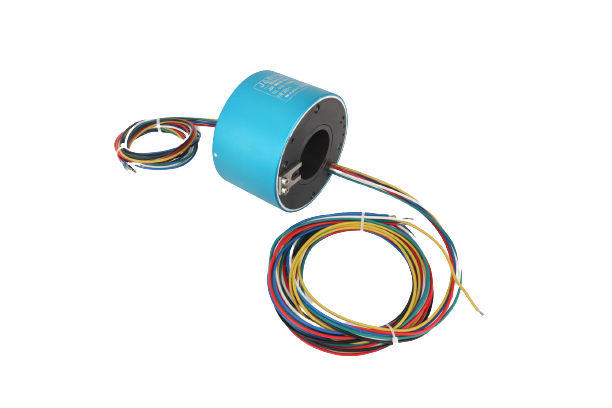

OVERVIEW

Outer diameter: 50mm

Number of encoder channels: 1-4 channels

Number of power/signal channels: 1-72 channels Voltage: 0-380VAC/VDC

Electrical Technical Parameters |

Power | Signal |

Spec. | data | Spec. | Data |

Voltage range | 0-380VAC/VDC | Voltage range | 0-380VAC/VDC |

Insulation Resistance | ≥1000MΩ/500VDC | Insulation Resistance | ≥1000MΩ/500VDC |

Lead wire spec. | AWG16# Tinned Teflon | Lead wire spec. | AWG22# Tinned Teflon |

Rated current | Optional current for each channel |

Electrical noise | 10mΩ@6VDC,50mA,5Rpm |

Dynamic resistance change | <0.01Ω |

Mechanical Data |

Mechanical Performance | Environmental Performance |

Spec. | Data | Spec. | Data |

Working Life | > 50 million revolutions (depends on working conditions) | Operating Temperature | -30C°-80C° |

Rated Speed | 300MRP(can be customized ) | Working Humidity | 0-85%RH |

Contact Material | Precious Metal (can be customized ) | Mechanical Vibration | MIL-SID-810E |

Shell Material | Aluminum Alloy (surface hard oxidation treatment) | IP Grade | IP51( IP65、IP68 Optional) |

Rotational Torque | 0.1N.M;+0.03N.M/ channel |

Options (Based on requirements)

1)Size(Inner Diameter, Outer Diameter, Length)

2)Current

3)Voltage [AC/DC] (max.)

4)Circuits quantity

5)Cable Length

6)Temperature Range

7)Operating Speed (max.)

JSR-SM025-XX Series Servo Motor Encoder Slip rings Table |

Model No.: | Power cable (4 cores, 10A per core) | Encoder control cable (6 cores with shield) | Signal Circuits(5A) | Power Circuit (20A) | Length(L/MM) |

SM025-01A10 | 1 | 1 | 0 | 0 | 65.6 |

SM025-01A10-6S | 1 | 1 | 6 | 0 | 86 |

SM025-01A10-12S | 1 | 1 | 12 | 0 | 106.4 |

SM025-01A10-18S | 1 | 1 | 18 | 0 | 126.8 |

SM025-01A10-24S | 1 | 1 | 24 | 0 | 147.2 |

SM025-01A10-6P20-12S | 1 | 1 | 12 | 6 | 147.2 |

SM025-01A10-36S | 1 | 1 | 36 | 0 | 191 |

SM025-02 | 2 | 2 | 0 | 0 | 106.4 |

SM025-02A07-6S | 2 | 2 | 6 | 0 | 126.8 |

SM025-02A07-12S | 2 | 2 | 12 | 0 | 147.2 |

SM025-02A07-18S | 2 | 2 | 18 | 0 | 167.6 |

SM025-02A07-24S | 2 | 2 | 24 | 0 | 191 |

SM025-02A07-6P20-12S | 2 | 2 | 12 | 6 | 191 |

SM025-02A07-36S | 2 | 2 | 36 | 0 | 231.8 |

SM025-03A05 | 3 | 3 | 0 | 0 | 147.2 |

SM025-03A05-6S | 3 | 3 | 6 | 0 | 167.6 |

SM025-03A05-12S | 3 | 3 | 12 | 0 | 191 |

SM025-03A05-18S | 3 | 3 | 18 | 0 | 211.4 |

SM025-03A05-24S | 3 | 3 | 24 | 0 | 231.8 |

SM025-03A05-6P20-12S | 3 | 3 | 12 | 6 | 231.8 |

SM025-03A05-36S | 3 | 3 | 36 | 0 | 275.6 |

SM025-04A10 | 4 | 4 | 0 | 0 | 191 |

SM025-04A10-6S | 4 | 4 | 6 | 0 | 221.4 |

SM025-04A10-12S | 4 | 4 | 12 | 0 | 231.8 |

SM025-04A10-18S | 4 | 4 | 18 | 0 | 262.2 |

SM025-04A10-24S | 4 | 4 | 24 | 0 | 275.6 |

SM025-04A10-6P20-12S | 4 | 4 | 12 | 6 | 275.6 |

SM025-04A10-36S | 4 | 4 | 36 | 0 | 316.4 |

Note: N pieces of 5A current loops can be used as 1 channel of N*5A current loop; For example, 2 rings 5A can be used as 1 circuit 10A.*If no standard models are suitable, contact us for custom solutions directly, thanks. |

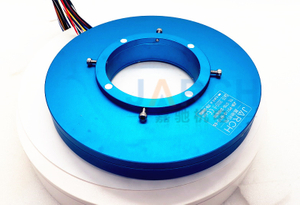

DIMENSION DRAWING

It is only a drawing example here. Normally it is OEM models as our customer's request,

Every design is based on different requirement.

The slip rings size are based on the circuits quantity ,current, voltage, speed and temperature...

Color Code For Lead Wires

Ring No. | Wire Color | Ring No. | Wire Color |

1 | Black | 7 | Purple |

2 | Red | 8 | Grey |

3 | Yellow | 9 | Orange |

4 | Green | 10 | Brown |

5 | Blue | 11 | Transparent |

6 | White | 12 | Light Green |

(Note: 12 colors are a group, with serial numbers 1...12, the next group repeats the first 12 colors, and each group is identified by a number tube as the group serial number.) |

INSTALLATION INSTRUCTION

MODEL NO.

APPLICATION FIELD

Robotics, CNC Machines, Automated Manufacturing Systems, auto package machines, Aerospace and Defense, Renewable Energy, Medical equipment, Automated Conveyor Systems

PACKAGE & DELIVERY

Package is by carton or by wooden.

Delivery: By Air, by Express, or by sea. Up to customers’ request.

The Servo Motor Encoder Slip Ring is designed to handle the specific requirements of transmitting signals between a servo motor and its encoder. It typically consists of various conductive rings, brushes, and insulation components that enable the transfer of data even during rotational movement.

This specialized slip ring is crucial in applications where maintaining accurate positioning and control of the servo

motor is essential. It ensures that the motor's encoder can continuously communicate with the system, allowing for precise feedback and control even as the motor is in motion.

Servo Motor Encoder Slip Ring Can provides the following advantages:

1.Continuous Rotation: A Servo Motor Encoder slip ring allows for unlimited rotations in a servo motor system. It ensures that the encoder can rotate continuously without any limitations imposed by the need to manage wires or cables

2.Uninterrupted Signal Transmission: A Servo Motor Encoder slip ring make sure the transmission of signals from the encoder to the control system without any interruptions, even as the motor rotates.

3.Reduced Wear and Tear: Without a A Servo Motor Encoder slip ring, cables or wires connected to the encoder might get twisted or damaged due to continuous rotation. With the A Servo Motor Encoder slip ring can be minimizes wear and tear on the cables, enhancing their longevity and reliability.

4.Precision and Accuracy: A A Servo Motor Encoder slip ring ensures that the encoder maintains a constant connection, which is crucial for precise control and accuracy in servo motor applications. It helps in providing continuous feedback without any signal losses.

5.Maintenance and Durability: A Servo Motor Encoder slip ring are designed for longevity and require minimal maintenance. When properly installed and maintained, they contribute to the durability and reliability of the system.

6.Customed and Mergerability: Servo Motor Encoder slip ring are available in various designs and configurations, allowing for customization based on specific application requirements. They can handle different types of signals (analog, digital, power) simultaneously.

7.High Reliability: These Servo Motor Encoder slip ring are built to offer high reliability, ensuring the continuous transfer of electrical signals or data without interruptions during the rotational movement of the servo motors.

8.High Rotational Speeds and Torque Support: They are engineered to support the rotational speed and torque requirements of the servo motors, ensuring smooth operation even at high speeds.

9.Low Electrical Noise: To ensure signal integrity, Servo Motor Encoder slip ring are designed to minimize electrical noise and interference, maintaining the quality of the transmitted data.

It is only some series model samples here. If it can not find the model you need.

Contact us here. Let us know with your requirements. Our JARCH designer & engineer team have the full experiences to custom design and produce high reliable slip rings/rotary unions/rotary joints/connectors for you.